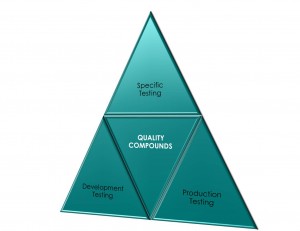

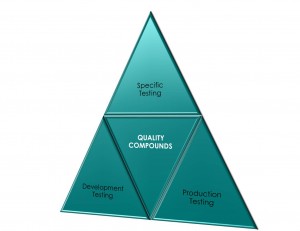

Eastland Compounding has a three stage approach to testing in order to ensure the continued high quality of all our bespoke rubber compounds.

This triangle comprises; day-to-day production testing, specific testing and development testing. Together, these create the Eastland Compounding ‘Triangle of Testing’.

Production Testing

Every batch of rubber compound produced by Eastland Compounding is tested meticulously for various properties, including; hardness and MDR testing for every ‘cures in’ batch.

Masterbatch compounds are tested for specific gravity and ML1+4.

Rubber packing temperature is also monitored to ensure conformance.

Specific Testing

In order to meet your bespoke rubber compounding needs specific testing can be completed upon request in our on-site Technical centre. Some examples of specific testing can be found below:

– Tensile Testing

– Tear Strength

– Stress Relaxation

– Heat ageing Testing

– MDR Rheometer

– Dispergrader for dispersion analysis

– Compression Set

– Volume Swells

– Electrical Resistance

– Abrasion Resistance

Once the rubber compound is made the high level of testing continues into post-production to ensure the compound reaches you in the best possible condition. All results are supplied on each certificate of conformance with every delivery.

Eastland Compounding can also utilise development testing in order to re-validate your compound.

Development Testing

In addition to day-to-day production testing and more specific testing, Eastland Compounding can leverage our technical capabilities in order to develop your rubber compound needs.

Development testing can be carried out in our on-site dedicated Technical Centre subject to your final design requirements.

Any development testing required can be achieved using the full scope of our on-site Technical Centre.